Phase One

Bill is building the cabin of his dreams....OK, it is a converted playhouse for the kids, who are too old to play in it....I mean, what other cabin can boast all the comforts of home? But, what good is a cabin without a grill to cook up some tasty steaks?

Bill was spurred into action when Caren gave him a wonderful gift...an electric cement mixer! Great, tools are good. Hey, wait a minute...when you give a woman a gift that allows her to do more work (like a vacuum cleaner, or a really nice set of sauce pans) you get nothing but grief in return. Why is that? Hmm...

Unfortunately, Bill was burned (sorry for the cheap pun) by his last BBQ building project. That grill suffered a significant structural failure, and developed a large crack. The MAIN objective in this construction is to avoid the dreaded crackage. As a result, this grill is completely OVER-engineered.

Well, Bill and Carl started Phase One by purchasing some 3/4 inch plywood, multiple bags of Quikrete and one of the hottest Saturdays we have seen yet...

First they poured the footing, or base.

This is laid directly on the limestone of the bluff, so I don't think it is going anywhere. The rebar is driven about 6" into the ground, so I think it shouldn't slide or shift....

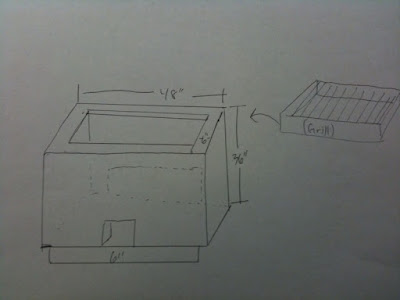

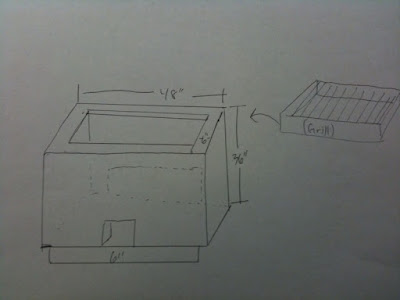

The next part was to build the forms for the upper portion. At first, it was going to be a simple 36"x48" box with 6" thick walls, with a small clean out/vent in the front and back. The shelf for the wood to lay on was going to be some 5/8" rebar spaced on 2" centers. Here is where we made our first design changes....We decided that a larger door was needed in the back so allow access for cleaning out old wood and ashes. We figured that bigger is better, so thought we would make it extend across the entire back. Well, we measured in 6" from each side of the form we were building.....but forgot that this form is the INSIDE form, not the outside form. DOH!

But here is where the wheels started to fall off the bus....

As any knowledgeable reader will readily observe, we have some design flaws...

There is some suspicion that the row of rebar that is forming the support to put the wood on may actually weaken the concrete, since it is so close together, and may expand and cause the dreaded crack. Also, see those 4 pieces of rebar that are in the "legs" is not actually going to end up in the wall of the structure. It is going to be running through the interior! Oops. Carl, was that your idea? Yeah, lets blame Carl, he isn't here to defend himself...

I have included the diagram below to help the reader understand the defeciencies of the current design. As you can see, we have some work to do. So much for grill designed by committee!

The next step will be to re-evaluate our design, and see if we can hire a grill construction consultant. Once we engage the services of a Consultant, we should see costs skyrocket, and the inevitable construction delays will begin! Bring it on!

More to come....

.jpg)

John was also able to fabricate our custom front and back doors. Here they are in their rough form. Once painted and ready to install, the fit and workmanship was pretty amazing!

John was also able to fabricate our custom front and back doors. Here they are in their rough form. Once painted and ready to install, the fit and workmanship was pretty amazing!

If you look at the corners and partway down the sides you will notice some small 2x4 blocks. It was originally thought that this would give a nice, "custom" touch to the corners. However, it became apparent that the odds of getting this to turn out correctly was low. It was likely that we could knock the corners off when we removed the forms, to the 2x4 were removed.

If you look at the corners and partway down the sides you will notice some small 2x4 blocks. It was originally thought that this would give a nice, "custom" touch to the corners. However, it became apparent that the odds of getting this to turn out correctly was low. It was likely that we could knock the corners off when we removed the forms, to the 2x4 were removed.